SIA “Field and Forest” develops zero-waste manufacturing technologies

Organic farming experts and essential oil manufacturers SIA “Field and Forest” in production process generates a large amount of by-products. Entrepreneurs and IES’s researchers cooperate in order to eliminate waste across the entire production value chain. IES’s researcher Laura Pastare highlights: “manufacturers, which use natural resources should use everything that they have taken from nature. If there is a large amount of plant material by-products, we have to look for ways to use it further. It is a sustainable approach that is based on circular economy principles.”

Both entrepreneur and IES’s researchers saw a high potential in steam distillation process by-products. Laura Pastare describes why these by-products were chosen for organic insect repellent development: “although these are production by-products, plant biomass still contains high concentration of valuable active substances. Within this research we are developing new extraction technologies. Therefore, waste can be reused - obtained extracts are a base for new product development.”

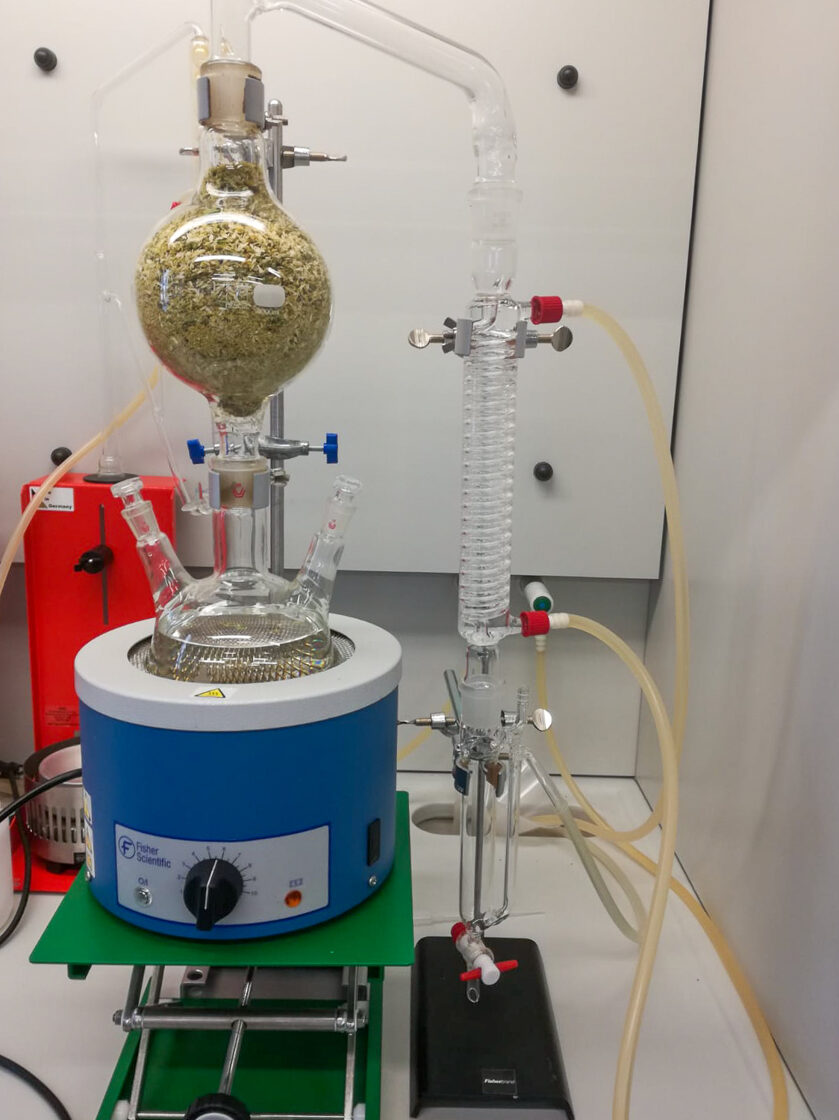

Essential oil distillation plant. Image: SIA “Field and Forest”.

Chamomile is harvested in summer, therefore during the last research period (summer 2021) IES’s researchers have looked in depth at chamomile production by-products. Until now, the development of extraction technologies has been carried out in small quantities at 15-litre distillation plants. Researchers are experimenting to understand how to obtain extracts with the highest active compound concentration. Different distillation factors are tested – water and plant biomass ratio, temperature, and length of the process.

The quality of the extracts obtained from experiments are evaluated in IES’s chemical analysis laboratory. These tests provide an insight into how different extraction experiments impact the quality – which active substances can be found in these extracts and how high is the concentration. Results show that extracts contain a high concentration of biologically valuable active compounds.

Extraction experiments are ongoing. Technologies that showcased the best results in chemical analysis will be transferred to industrial-scale essential oil distilling plants. This is necessary to compare differences in obtained results – does extracting in industrial quantities showcase the same quality of chemical composition as in small scale extraction. Industrial scale trials also give an opportunity to assess the economic aspects of extraction and production processes. Laura Pastare explains: “Entrepreneurs need information not only about the concentration of active substances, but also the economic basis of extraction and processing.”

Steam delivery system for essential oil distillation container. Image: SIA “Field and Forest”.

Next step of this research is the evaluation of obtained extracts to determine the effects on insects and plants. IES’s researcher Kristīne Berķe-Ļubinska: “there are currently no widely available substances on the global market for plant protection that are registered as insect repellents suitable for organic farming. Our task within this research is to evaluate how obtained extracts change behaviour of insects. These tests will be done in IES’s entomology laboratory. We are looking for extracts that repel insects from the plants.”

The research is a part of the project “Essential oil distillation waste streams as a potential source of sustainable plant-based repellent products” (No. Nr. 1.1.1.1/20/A/096). It is developed as a part of the European Regional Development Fund programme 1.1.1.1 measure “Support for applied research” and specific objective 1.1.1 “Improve research and innovation capacity and the ability of Latvian research institutions to attract external funding, by investing in human capital and infrastructure”.

More about the project here.